Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Produk-produk

Tahap Automasi: Automatik

Tekanan Nominal (kN): 1000

Jenis Mesin: Disegerakkan

Panjang Meja Kerja (mm): 4000

Lama Dan Baru: Baru

Tempat Asal: China

Bahan Yang Boleh Dimesin: Keluli tahan karat, SEMUA, Keluli karbon, Aluminium

Ciri-ciri Tambahan: Pembentukan Akhir

Persijilan: ISO 9001: 2000

Titik Jualan Teras: Ketepatan tinggi

Tempoh Jaminan: 1 tahun

Perkhidmatan Di Luar Jaminan: Sokongan teknikal video, Sokongan dalam talian, Alat ganti

Industri Yang Berkenaan: Kedai Bahan Binaan, Kedai Pembaikan Jentera, Loji Pembuatan, Ladang, Restoran, Runcit, Kerja-kerja pembinaan, Syarikat pengiklanan

Di Mana Menyediakan Perkhidmatan Tempatan (di Mana Negara Ada Outlet Perkhidmatan Luar Negeri): Amerika Syarikat, Arab Saudi, Indonesia, Pakistan, India, Rusia, Bangladesh, Ukraine, Uzbekistan

Lokasi Bilik Pameran (di Negara Mana Terdapat Bilik Sampel Di Luar Negara): Australia

Jenis Pemasaran: Produk Terhangat 2019

Laporan Ujian Mekanikal: Dengan syarat

Pemeriksaan Kilang Video: Dengan syarat

Tempoh Jaminan Komponen Teras: 3 tahun

Komponen Teras: Motor, Pam, PLC

Machine Type: Press Brake

Prestasi & Ciri:

A: High-configuration, high-precision, high-efficiency full CNC sheet metal Press Brake

B: The frame is integrally welded and heat treated. The overall machining of the boring machine has high precision and good rigidity

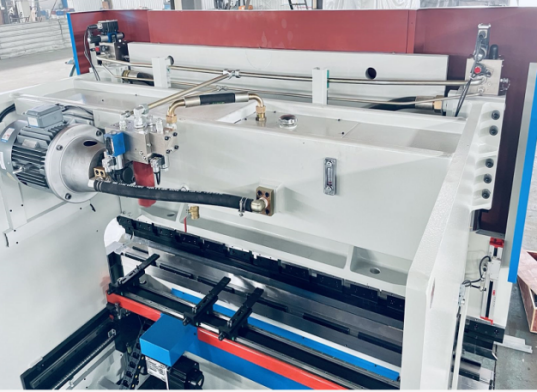

C: This machine adopts imported high-performance hydraulic system and internal gear pump

D: Standard 3+1 Axis, equipped with Delem DA53T System

E: Siemens main motor, Schneider Electric

Optional Configuration:

A: Multi-Axis options: 4+1, 6+1, 8+1...

B: Laser guards, as well as side and rear fence protection

C: CNC System: DA58T, DA66T

D: Main Servo Motor

Frame part: This part is a frame-shaped structure, which consists of a workbench vertical plate, left and right side plates, connecting beams, and mechanical deflection compensation devices. The steel plate is welded as a whole, with good rigidity, high strength, and good resistance to distortion and deformation; internal stress is eliminated through surface shot peening and other processes to ensure the lasting stability of the overall accuracy of the machine tool; the upper slide plate and worktable are deformed during bending Small quantities ensure the work-piece has excellent straightness and angular consistency.

Upper slide part: the left and right oil cylinders are tightly connected with the frame with bolts, and the piston rod of the oil cylinder and the slider are connected with a spherical gasket and a screw rod. Combination performance with the slider; the slider and the frame are connected by a rectangular guide rail pair with self-lubricating function; magnetic scales are installed on the C-shaped plates on both sides of the frame to detect and feed back the synchronous movement state of the two oil cylinders to ensure Controls the slider travel position.

|

|

Mold and clamping device: The mold is composed of upper mold and lower mold, which is of high quality and durable. The upper die is installed on the slider and fixed by a precise quick clamping device, and the lower die adopts the double V concentric form, which is convenient and quick to change the die, reduces labor intensity and improves production efficiency.

Front support bracket for linear guide rail: This part is a standard part and is installed on the front of the worktable. When in use, the material support bracket can be manually moved to an appropriate position through the linear guide rail according to the length of the work-piece , and the material support bracket can be adjusted in the horizontal and vertical directions.

Throat deformation compensation device with special structure: a grating ruler is installed on both sides of the machine tool to measure and feedback the precise distance between the slider and the lower table. The grating ruler is connected with the worktable through the C-shaped frame, which completely eliminates the influence of the deformation of the throat of the frame on the position of the slider; the position data of the slider is fed back to the numerical control system, and the output signal of the numerical control system controls the hydraulic proportional servo valve It controls the actions of the two sets of electro-hydraulic proportional servo valves respectively, so that the two oil cylinders can keep precise synchronization. This structure can make the machine have anti-eccentric load ability, and can effectively prevent non-standard work-piece from colliding with the interference grating ruler.

Back gauge device: The latest self- design of the precise and stable back gauge device is adopted, and the servo motor drives the ball screw, which has the characteristics of high speed and high positioning accuracy; the novel and unique double linear guide structure ensures the highest positioning accuracy; more The high-grade gear design increases the positioning range, and the value for money is excellent; the modular design, the number of control axes can be selected from single-axis X, optional to multi-axis.

Data teknikal:

|

Parameter & Specification |

Nominal Pressure (KN) |

Worktable Length (mm) |

Distance between uprights (mm) |

Throat Depth (mm) |

Ram Stroke (mm) |

Max Opening Height

(mm)

|

Main Power (Kw) |

|

WE67K-40/2000 |

400 |

2000 |

1700 |

200 |

120 |

390 |

4 |

|

WE67K-63/2500 |

630 |

2500 |

2000 |

250 |

150 |

420 |

5.5 |

|

WE67K-100/2500 |

1000 |

2500 |

2700 |

400 |

200 |

470 |

7.5 |

|

WE67K-100/3200 |

3200 |

3300 |

|||||

|

WE67K-160/3200 |

1600 |

3200 |

2700 |

400 |

200 |

470 |

11 |

|

WE67K-160/4000 |

4000 |

3300 |

|||||

|

WE67K-200/3200 |

2000 |

3200 |

2700 |

400 |

200 |

470 |

15 |

|

WE67K-200/4000 |

4000 |

3300 |

|||||

|

WE67K-250/3200 |

2500 |

3200 |

2700 |

400 |

250 |

520 |

18.5 |

|

WE67K-250/4000 |

4000 |

3300 |

|||||

|

WE67K-250/5000 |

5000 |

4300 |

|||||

|

WE67K-300/3200 |

3000 |

3200 |

2600 |

400 |

250 |

520 |

22 |

|

WE67K-300/4000 |

4000 |

3300 |

|||||

|

WE67K-300/5000 |

5000 |

4000 |

|||||

|

WE67K-300/6000 |

6000 |

4800 |

|||||

|

WE67K-400/4000 |

4000 |

4000 |

3300 |

400 |

320 |

630 |

30 |

|

WE67K-400/5000 |

5000 |

3920 |

|||||

|

WE67K-400/6000 |

6000 |

4720 |

|||||

|

WE67K-400/7000 |

7000 |

5020 |

|||||

|

WE67K-500/4000 |

5000 |

4000 |

3000 |

400 |

350 |

650 |

37 |

|

WE67K-500/5000 |

5000 |

3800 |

|||||

|

WE67K-500/6000 |

6000 |

4600 |

|||||

|

WE67K-500/7000 |

7000 |

5600 |

|||||

|

WE67K-600/5000 |

6000 |

5000 |

3900 |

500 |

320 |

650 |

55 |

|

WE67K-600/6000 |

6000 |

4800 |

|||||

|

WE67K-600/7000 |

7000 |

5400 |

|||||

|

WE67K-600/8000 |

8000 |

6000 |

|||||

|

WE67K-800/6000 |

8000 |

6000 |

4800 |

600 |

400 |

920 |

55 |

|

WE67K-800/7000 |

7000 |

5100 |

|||||

|

WE67K-800/8000 |

8000 |

6100 |

|||||

|

WE67K-800/10000 |

10000 |

7800 |

|||||

|

WE67K-1000/6000 |

10000 |

6000 |

4800 |

600 |

400 |

920 |

37X2 |

|

WE67K-1000/7000 |

7000 |

5100 |

|||||

|

WE67K-1000/8000 |

8000 |

6100 |

|||||

|

WE67K-1000/10000 |

10000 |

7800 |

|||||

|

WE67K-1200/6000 |

12000 |

6000 |

4800 |

600 |

400 |

920 |

45X2 |

|

WE67K-1200/7000 |

7000 |

5100 |

|||||

|

WE67K-1200/8000 |

8000 |

6100 |

|||||

|

WE67K-1200/10000 |

10000 |

7800 |

Kategori produk : Tekan brek > WE67K Brake Press Electrical-Hydraulic Press

Nantong Xintongwei Alat Mesin Co. , Ltd Terletak di bahagian timur Plain Jiangsu Tengah, "kampung halaman Ricih Cina, alat mesin lipat dan rolling" - Haian Libao. Ia bersebelahan dengan Laut Kuning di timur, Sungai Yangtze di selatan, Xinchang Railway di barat, dan dekat dengan lebuh raya nasional 204 dan 328. Syarikat itu dahulunya dikenali sebagai "Kilang Alat Mesin Haiian Haiwei yang asal." Mengkhususkan diri dalam pengeluaran siri jenama " Tongwei " mesin ricih, mesin lentur, mesin rolling, mesin meratakan, mesin slitting, talian pengeluaran yang tidak bersatu dan meratakan dan peralatan pemprosesan logam lembaran lain. Syarikat mempunyai sekumpulan profesional yang telah terlibat dalam Menambah reka bentuk untuk masa yang lama. Melalui persekutuan yang kuat dengan pelbagai institut penyelidikan dan penempatan dan institusi penyelidikan teknikal utama, struktur produk terus meningkat, dan penerapan teknologi baru berada dalam kedudukan utama dalam industri yang sama. , supaya prestasi seluruh mesin mencapai tahap maju antarabangsa, dan ia merupakan pengganti ideal untuk alat mesin yang diimport. Dalam beberapa tahun kebelakangan ini, syarikat telah membangunkan beberapa struktur baru dan teknologi baru, dan memohon beberapa paten. Produk-produk ini telah meluluskan pengawasan dan pemeriksaan kualiti dan perbandaran dan perbandaran untuk beberapa kali, dan telah memenangi gelaran kehormat "kontrak-penghormatan dan menjanjikan" perusahaan ". Produk syarikat digunakan secara meluas dan dijual di seluruh negara dan dieksport ke Asia Tenggara, Asia Barat, Afrika, dan Rusia dalam beberapa tahun kebelakangan ini. Dan negara -negara Eropah yang lain, mempunyai tempat di pasaran Eropah dan Amerika. Syarikat itu mematuhi prinsip "Kualiti Pertama. Perkhidmatan Pertama. Reputasi Pertama", mengambil kepuasan pelanggan sebagai prinsip operasi, dan menegaskan untuk menyediakan pelanggan dengan perkhidmatan pra-jualan, jualan, dan jualan selepas jualan yang bijak.

Pengurusan Perusahaan, Jaminan Kualiti, Sistem Reka Bentuk Produk

Pada tahun 1998, reka bentuk bantuan komputer CAD telah dilaksanakan sepenuhnya

Pensijilan Sistem Kualiti ISO9001-2000 yang diluluskan pada bulan Mac 2002

Persijilan Sistem Kualiti CE yang diluluskan pada bulan Jun 2009

Kelayakan perusahaan

Unit Kredit Gred AAA

Memenangi gelaran "Kontrak-Honoring dan Janji-Penjagaan Perusahaan"

Memenangi gelaran "Produk Berkualiti Berkualiti di Wilayah Jiangsu"

Memenangi "Lesen Kualiti Produk Eksport"

Home > Produk-produk > Tekan brek > WE67K Brake Press Electrical-Hydraulic Press > 130ton Press Brake Servo digerakkan 3+1 paksi

Hantar pertanyaan

Mr. Jiang

Tel:86-0513-88285180

Fax:

Telefon mudah alih:+8618806279855

E-mel:east@cnxtw.com

Alamat:Hongqi Private Area, Libao Town, Haian City, Nantong, Jiangsu

Tapak Mudah Alih

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.